PRODUCTS

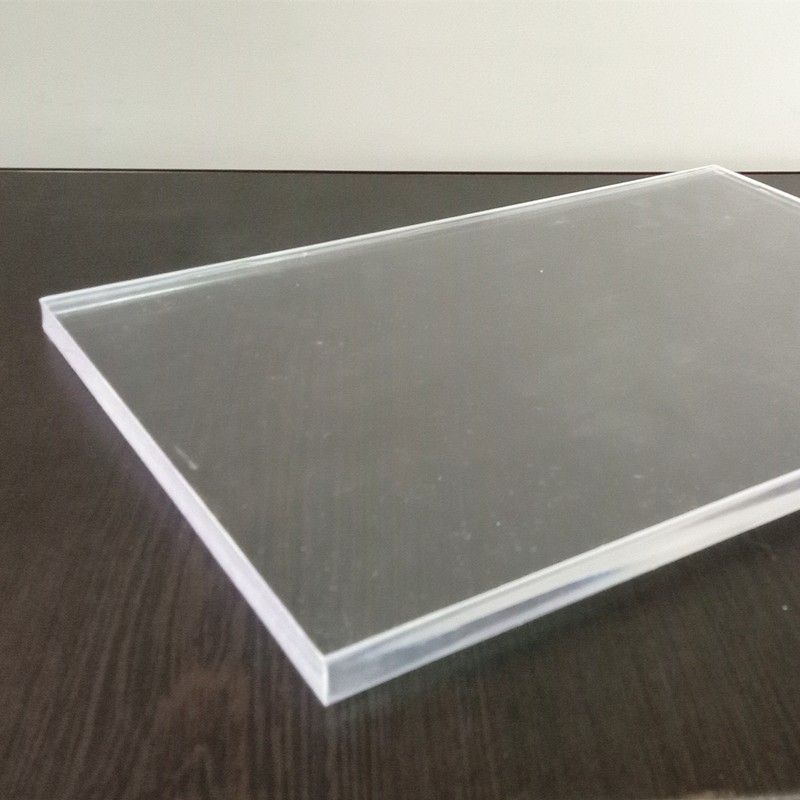

pmma clear acrylic sheet cast thermoplastic acrylic sheet

Brand : Rensino Plastic Sheet

Product origin : China, Shandong

Delivery time : contact us

Supply capacity : 500 Ton/Tons per Month

pmma clear acrylic sheet cast thermoplastic acrylic sheet

Material Composition and Performance: Our plastic sheets are manufactured using premium raw materials such as virgin PMMA, rigid PVC, PP, PS, ABS, polycarbonate, and PETG. Each material is selected and processed for optimal performance, offering excellent clarity, impact resistance, weatherability, thermal stability, and chemical resistance. Product specifications such as thickness, hardness, tensile strength, and light transmission are available for all product lines.

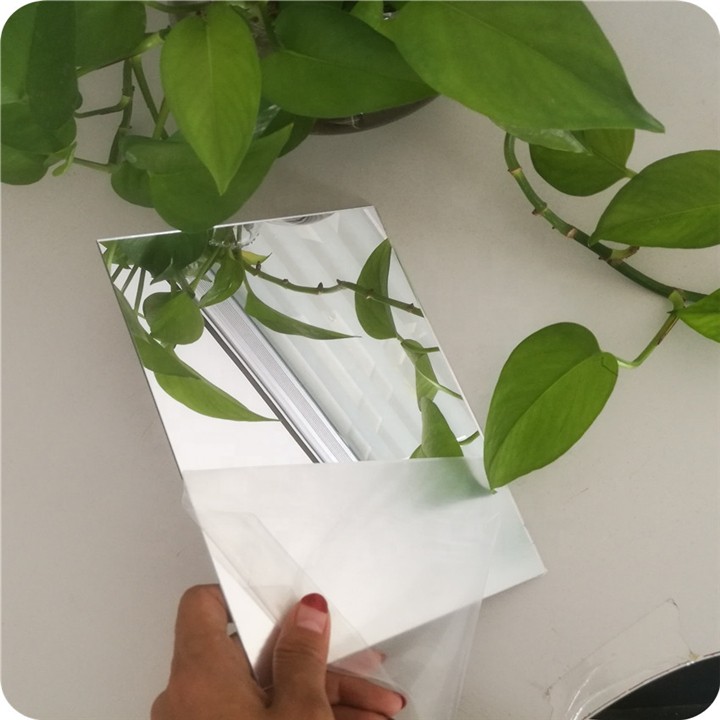

Surface Texture and Finish: We provide a wide variety of surface options, including glossy, matte, embossed, frosted, and patterned finishes. Additional treatments such as UV coating, anti-scratch layers, anti-fogging, or flame retardant formulations can be applied upon request to meet specific functional or aesthetic needs.

Color and Customization: Our sheets are available in clear, opaque, tinted, fluorescent, metallic, and custom Pantone-matched colors. We offer full customization in terms of size, thickness, transparency, surface texture, and functional properties. Logo printing, laser engraving, protective masking films, and multi-layer co-extrusion are also supported for OEM/ODM projects.

Application Versatility: Rensino plastic sheets are widely used in industries such as signage, advertising, construction, packaging, lighting, furniture, retail displays, and industrial equipment. Each product line can be customized to meet the technical, visual, and regulatory requirements of different markets and applications.

Introduction

Feature of acrylic sheet: |

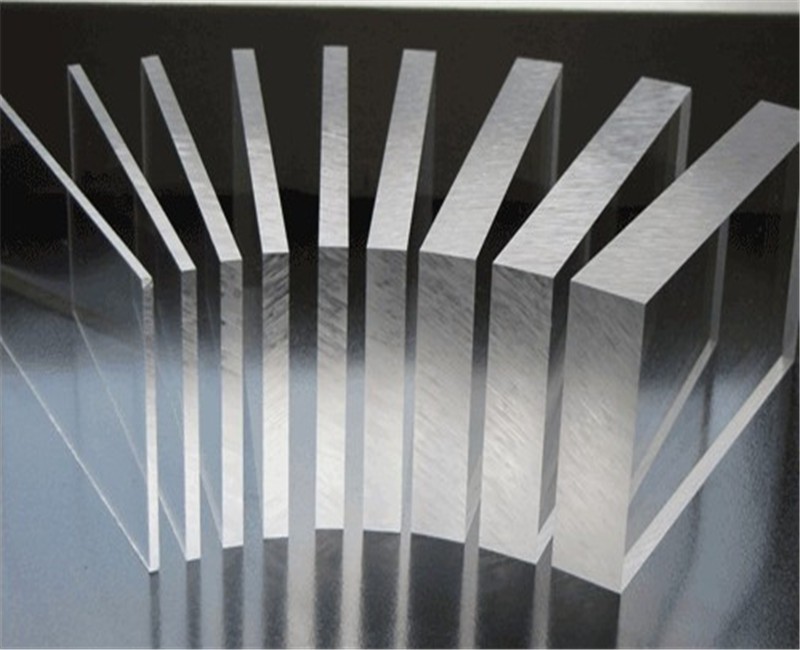

v Perfect transparency and the light transmittance with 93%. |

v Excellent electrical insulation, very light in weight. |

v High plasticity, Processing and shaping easier. |

v Strong surface hardness and good weather resisting property |

v Beautiful in colour, easy to clean |

Applications |

v Construction: show window, doors, light-absorpting shade, telephone booth. |

v Advertisement: lamphouse,signboard,indicator,display rack. |

v vehicle: door and window of car and train. |

v Medical: infant incubator, many kinds of medical apparatus. |

v Civilian goods: bath room, art work, cosmetics, bracket. |

v Industrial: instruments and meters and protecting cover |

v Lighting: daylight lamp, ceiling lamp,lampshade |

Promotion |

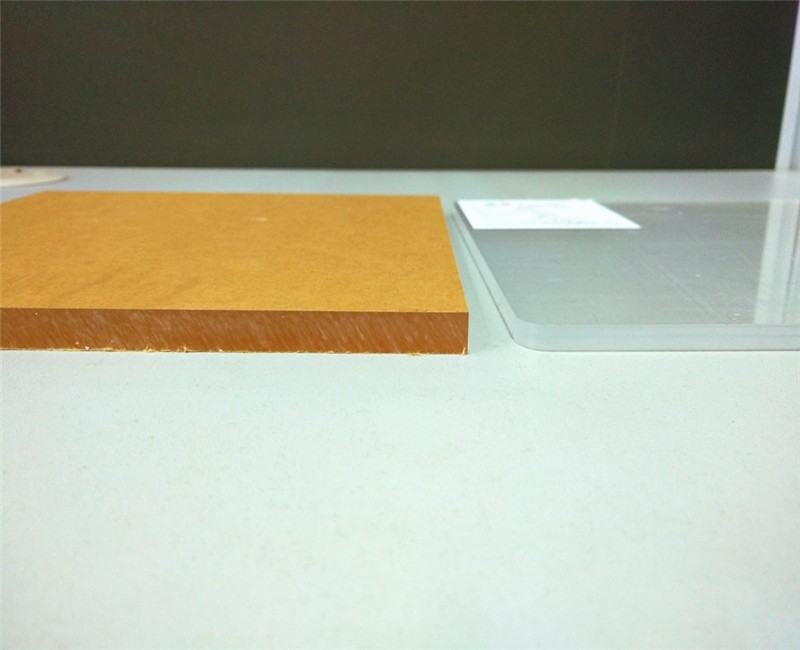

v standard size 1220*2440mm,1220*1830mm,2000*3000mm v edge included size 1260*2480mm,1260*1880mm,2050*3010mm v thickness 2mm-200mm v color red, white,yellow,orange,black,etc, as the client's request v surface frosted,smooth, mirror,double side mirror v inside shining cotton gold,silver or other color and other thing like leaf v tolerance 0.1mm-0.2mm,according to the thickness of the sheet v cutting service we can cut the sheet into any size to meet your demand |

Acrylic Average Physical Properties |

v HardnessM-100 v Absorptivity of water (24h)0.30% v Coefficient of Rupture700kg/cm2 v Coefficient of Elasticity28000kg/cm2 v Coefficient of Rupture1.5kg/cm2 v Coefficient of Elasticity28000kg/cm2 v Transmittance (parallel rays)92% v Full rays93% v Heat Distortion Temperature100oc v Coefficient of Linear Expansion v UltimaeTemperatureof Continuous operation 80oc v Thermoforming Ranges140-180oc v Insulation Strength20V/mm |

Notes: 1. acrylic sheet is likely to expand when the temperature is over 100°C, so the continuous temperature don’t exceed 90°C. 2.Space between acrylic sheets should be left out when construction, regarding the weight, load and temperature. 3.The surface hardness of acrylic sheet is as hard as aluminum alloy; Polish it with the abrasive material for aluminum when it is scratched in abnormal condition. 4. Acrylic sheet can cause static; clean the surface with mull dipping 1% suds 5. Keep the warehouse dry and well-ventilated, and from fire. 6. Use elastic material such as rubber when processing base material. WHY CHOOSE US? 1 Imported glass models (from Pilkington Glass in U. K. ), Taiwan production line, 100% pure raw Lucite material. 2 Main products cover excellent quality cast acrylic sheet and PVC foam sheet. Focus on this field for 20 years. 3 The thickness of sheet could be made from 0.5mm to 30mm.the capacity could reach 7000 tons per year.

|

Rensino Plastic Sheet Co., Ltd. has been deeply involved in the plastic sheet industry for many years, offering a comprehensive portfolio that includes Acrylic Sheet, PVC Sheet, Acrylic Products, PP Corrugated Sheet, PS Sheet, ABS Sheet, Polycarbonate Sheet, and PETG Sheet. Each product line is engineered with specific performance characteristics—such as impact resistance, optical clarity, weatherability, flame retardancy, and eco-friendly options—to meet the diverse demands of industries including signage, construction, packaging, lighting, furniture, and industrial applications.

We sincerely welcome OEM/ODM cooperation and work closely with clients to develop plastic sheet materials tailored to their specific applications, technical specifications, and branding needs. Backed by an experienced R&D team, state-of-the-art production equipment, and a strict quality control system, we ensure a stable supply of high-performance materials that comply with international standards and certifications.

Please note that our website displays only a selection of our available products. If you have specific material requirements or need further technical information, feel free to contact us via phone or email. Our professional team is always ready to provide customized solutions that help you succeed in your market with the right plastic sheet materials.